Restylon Injection Molding Technologies

Depending on the desired result, a plastic article can be produced by Co-injection or Mono sandwich.

However, the two processes, although similar, have important differences.

Today, the communication of plastic material has taken on a negative connotation due to the quality of the material and its impact on the environment. However, in Maspi we intend to get another message through. As is quite often the case for other applications, it is not the object itself that creates pollution but its use. Like other materials, in fact, plastic does not pollute more and with the right attention can be reused in processes to give second-life materials a new use.

However, recycled materials cannot always be reused for the production of new items, especially in sectors with a high aesthetic impact. Nevertheless, in Maspi the binomial "recycled = poor quality" is permanently broken thanks to RESTYLON Co-injection technology.

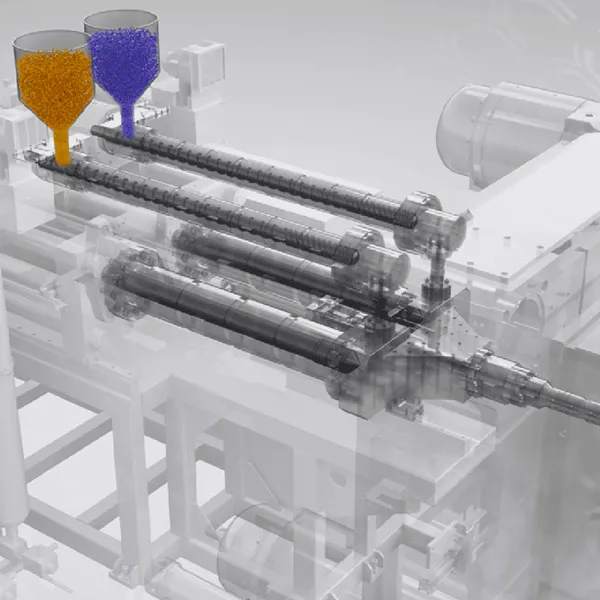

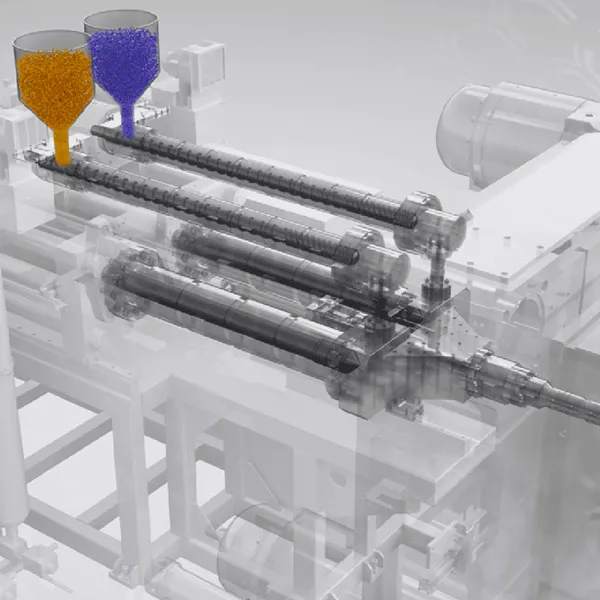

The innovative RESTYLON Co-injection or Mono sandwich system combines two compatible polymeric plastics, using at least 30 percent recycled material without compromising the fine aesthetics of the item. Moving beyond traditional molding, RESTYLON allows a strong reduction in CO2 emissions and the production of items with high thickness that can withstand higher pressures while avoiding possible deformation of the plastic object.

RECYCLED PLASTIC MATERIAL INCORPORATED INTO EACH CO-INJECTED ITEM

REDUCTION OF CO2 EMISSIONS WITH THE RE-USE OF MATERIALS

EVERY ITEM IS COMPLETELY RECYCLABLE AT THE END OF ITS LIFE

Depending on the desired result, a plastic article can be produced by Co-injection or Mono sandwich.

However, the two processes, although similar, have important differences.